Parker MHB-030-LEAH-08B

Load Control Valve

Parker’s piloted load control valves operate independent of downstream pressure to prevent runaway loads under dynamic conditions using a pilot signal, handling pressures up to 420 bar (6000 psi) and flows up to 350 lpm (90 gpm)

Parker’s piloted load holding/counterbalance valves are a combination of a relief, sequence, and flow control valve that can handle pressures up to 420 bar (6000 psi) and flows up to 350 lpm (90 gpm). These robust valves allow the operator to maintain control of the load by preventing it from overrunning the pump while also protecting against thermal expansion. The wide selection of pilot ratios enables the valve to open based off a given backpressure specific to the application, which could be much lower than the spring pressure setting. This feature allows predictable and consistent control of a load throughout its lowering cycle.

Markets:

• Aerial

• Construction Equipment

• Material Handling Equipment

• Miscellaneous Industrial

• Miscellaneous Mobile

Features/Benefits:

• Hardened, precision ground parts for durability

• Poppet style construction with minimal leakage

• Tamperproof versions available

• Single cartridge valve with integral reverse flow check valve

• Available pilot ratios 8:1 to 1.5:1

• All external parts zinc plated

Applications:

• Load holding

• Position holding

Additional Technical Insight:

The load control valves are load assisted i.e the pilot pressure acts on the difference between the setting and the load at the pilot ratio.

It should always be set at a minimum of 30% higher than the maximum load induced pressure to ensure the valve closes correctly.

Sizing a counterbalance valve needs care in that the flow required is usually higher than system pump flow, as in the case with a cylinder application (retract flow could be twice the system flow) though oversizing the valve could cause instability.

Because of dynamic load variations in many applications, it may be necessary to use a lower pilot ratio or fit an orifice in the pilot line in order to gain stability. The valve will be affected by backpressure and care must be taked with proportional and closed center systems.

Parker’s piloted load holding/counterbalance valves are a combination of a relief, sequence, and flow control valve that can handle pressures up to 420 bar (6000 psi) and flows up to 350 lpm (90 gpm). These robust valves allow the operator to maintain control of the load by preventing it from overrunning the pump while also protecting against thermal expansion. The wide selection of pilot ratios enables the valve to open based off a given backpressure specific to the application, which could be much lower than the spring pressure setting. This feature allows predictable and consistent control of a load throughout its lowering cycle.

Markets:

• Aerial

• Construction Equipment

• Material Handling Equipment

• Miscellaneous Industrial

• Miscellaneous Mobile

Features/Benefits:

• Hardened, precision ground parts for durability

• Poppet style construction with minimal leakage

• Tamperproof versions available

• Single cartridge valve with integral reverse flow check valve

• Available pilot ratios 8:1 to 1.5:1

• All external parts zinc plated

Applications:

• Load holding

• Position holding

Additional Technical Insight:

The load control valves are load assisted i.e the pilot pressure acts on the difference between the setting and the load at the pilot ratio.

It should always be set at a minimum of 30% higher than the maximum load induced pressure to ensure the valve closes correctly.

Sizing a counterbalance valve needs care in that the flow required is usually higher than system pump flow, as in the case with a cylinder application (retract flow could be twice the system flow) though oversizing the valve could cause instability.

Because of dynamic load variations in many applications, it may be necessary to use a lower pilot ratio or fit an orifice in the pilot line in order to gain stability. The valve will be affected by backpressure and care must be taked with proportional and closed center systems.

Technical Information

Division: Hydraulic Cartridge Systems Division

Maximum Flow Rate: 30 GAL/MIN, 112.5 L/MIN

Maximum Flow Rate: 30 Gal/min, 112.5 L/min

Pilot Pressure Ratio: 6:1

Pilot Pressure Ratio: 6:1

Adjustment Mechanism: Tamper Resistant

Mounting Type: Single Inline

Adjustment Mechanism: Tamper Resistant

Mounting Type: Single Inline

Holding Pressure: 3000 PSI, 210 BAR

Holding Pressure: 3000 psi, 210 bar

Pressure Control Range: 1500-3000 PSI, 105-210 BAR

Port Size: SAE-8

Seal Material: Nitrile

Pressure Control Range: 1500-3000 psi, 105-210 bar

Port Size: SAE-8

Seal Material: Nitrile

Flow Rate: 30 Gal/min, 112.5 L/min

Maximum Operating Pressure: 3000 psi, 210 bar

Maximum Inlet Pressure Rating: 3000 psi, 210 bar

Pressure Control Sensitivity: N/A psi, N/A bar

Function: Counterbalance Valve

Actuation Type: Pilot Operated

Pilot Location: External

Body Material: Aluminum

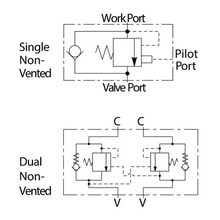

Flow Direction: Cylinder port C, Valve port V, Pilot port P

Leak Rate: 5 @ 80% of setting drops/min

Cavity Size: N/A

Installation Torque: N/A Nm, N/A lb-ft

For Fluid Type: Mineral-based or synthetic hydraulic fluids

Filter Efficiency Rating: ISO 4406 18/16/13, SAE Class 4

Maximum Kinematic Viscosity: 45-2000 SSU (6 to 420 cSt)

Valve Material: All parts steel. All operating parts hardened steel

Operating Temperature: -30 to +250 °F, -34 to +121 °C

Maximum Operating Temperature: +250 °F, +121 °C

Minimum Operating Temperature: -30 °F, -34 °C

Weight: 2.5 lb, 1.13 kg

Division: Hydraulic Cartridge Systems Division

Maximum Flow Rate: 30 GAL/MIN, 112.5 L/MIN

Maximum Flow Rate: 30 Gal/min, 112.5 L/min

Pilot Pressure Ratio: 6:1

Pilot Pressure Ratio: 6:1

Adjustment Mechanism: Tamper Resistant

Mounting Type: Single Inline

Adjustment Mechanism: Tamper Resistant

Mounting Type: Single Inline

Holding Pressure: 3000 PSI, 210 BAR

Holding Pressure: 3000 psi, 210 bar

Pressure Control Range: 1500-3000 PSI, 105-210 BAR

Port Size: SAE-8

Seal Material: Nitrile

Pressure Control Range: 1500-3000 psi, 105-210 bar

Port Size: SAE-8

Seal Material: Nitrile

Flow Rate: 30 Gal/min, 112.5 L/min

Maximum Operating Pressure: 3000 psi, 210 bar

Maximum Inlet Pressure Rating: 3000 psi, 210 bar

Pressure Control Sensitivity: N/A psi, N/A bar

Function: Counterbalance Valve

Actuation Type: Pilot Operated

Pilot Location: External

Body Material: Aluminum

Flow Direction: Cylinder port C, Valve port V, Pilot port P

Leak Rate: 5 @ 80% of setting drops/min

Cavity Size: N/A

Installation Torque: N/A Nm, N/A lb-ft

For Fluid Type: Mineral-based or synthetic hydraulic fluids

Filter Efficiency Rating: ISO 4406 18/16/13, SAE Class 4

Maximum Kinematic Viscosity: 45-2000 SSU (6 to 420 cSt)

Valve Material: All parts steel. All operating parts hardened steel

Operating Temperature: -30 to +250 °F, -34 to +121 °C

Maximum Operating Temperature: +250 °F, +121 °C

Minimum Operating Temperature: -30 °F, -34 °C

Weight: 2.5 lb, 1.13 kg

Can't Find A Part? Ask us!

We specialise in sourcing hard to find specials, oddballs & obsolete parts, get in touch if you can't see what you are looking for.

01555 772474

sales@uscltd.co.uk